Sustainable clay for 3D printing

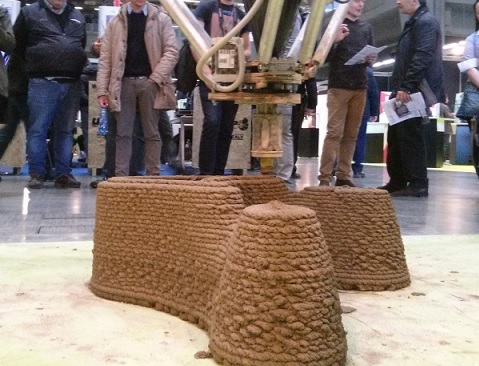

3D-printed buildings are already a reality, yet Texas A&M University researchers are taking it a step further, revolutionizing the construction industry with a greener method of printing using local soil. The results were presented at the American Chemical Society (ACS) Fall 2020 Virtual Meeting and Exposition, as an alternative to the use of concrete that produces a large carbon footprint.

Historically, humans used to build with locally sourced materials such as adobe, but the switch to concrete has raised many environmental issues, says Aayushi Bajpayee, a graduate student in Banerjee’s lab at Texas A&M University, who presented the new proposal together with his work team. The idea is to find a way to adapt the materials of the backyards as a possible replacement for concrete.

Construction projects with 3D technology using concrete have shown the potential of additive manufacturing in terms of reduced waste, faster and cheaper construction times; the materials used in the process must also be sustainable. An advantage of using local soil in construction is that materials do not need to be manufactured and transported to the construction site, reducing costs and environmental damage.

Soil is generally classified by the layers of materials it comprises, beginning with the top organic layer where plants grow and ending in the hard bedrock of the earth’s crust. Beneath the initial organic layer is clay, which gives the soil its plastic and moldable character that the researchers capitalized on in their project.

The researchers started the project by collecting soil samples from a colleague’s backyard, to which they adopted a new eco-friendly additive to bind and easily manipulate through the 3D printer.

The next step was to make sure that the mixture supported the load, that is, if it resisted the weight of the layers, or if it needed other materials such as reinforcement bars and insulation. To do this, the researchers strengthened the clay mixture by “closing” the microscopic layers on its surface, preventing it from absorbing water and expanding, which would compromise the printed structure. Using this method, the researchers showed that the material could hold twice the weight of the unmodified clay mixture.

Currently the team plans to improve the soil’s bearing capacities to expand its test structures and get as close as possible to a replacement for concrete. In addition, they are collecting data to see if these 3D printed structures are as environmentally friendly as they imagine, especially in terms of carbon footprint and recycling potential.

By Samantha García